With the state-of-the-art copper manufacturing facility in Hoskote, the multinational business conglomerate is looking at tapping a revenue of INR 270 crore by FY 25.

In a major development that aims to make India self-reliant in copper manufacturing, Bangalore-based, Gopalan Enterprises, a multinational business conglomerate with interest in real estate, aerospace, education, organic agriculture, and sports sectors, announces its foray into copper manufacturing. Gopalan Metals (India) Private Limited’s state-of-art copper manufacturing facility, with an annual production capacity of 6000 MT, is strategically located at Hoskote industrial area, Bengaluru.

Gopalan Metals aims to help cut India’s dependence on imports, address supply challenges, and aid clean energy transition for businesses, in the face of the rising cost of copper. The Bengaluru-based company is looking at a projected capacity of 3000 MT and revenue of INR 270 crore for FY 2024-25 from domestic and international markets.

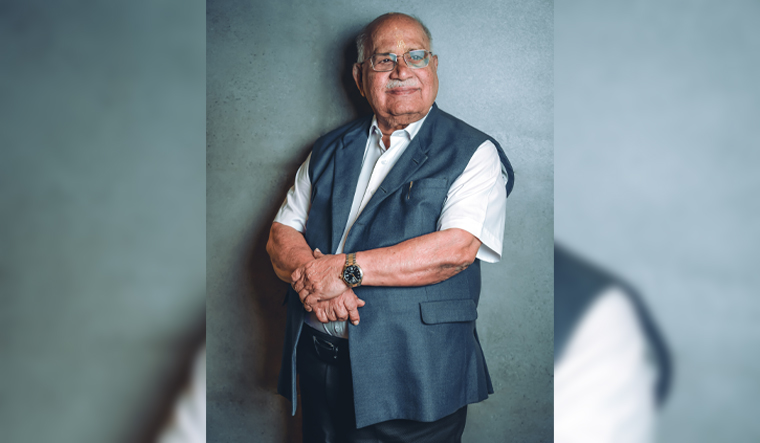

Commenting on the company’s vision, C Prabhakar,Director, Gopalan Enterprises, said, “India’s copper consumption is 1.5 million tonnes a year, and is expected to cross 2 million tonnes by 2030. The demand for copper products has grown enormously due to new age technology development, electrification of transport systems, and the push for renewable energy. Copper is 100 per cent recyclable, making it a crucial component for renewable energy technologies. The market demand is bound to continue to surge.”

“Currently, India imports nearly 30% of its copper requirement. At Gopalan Metals, we are determined to reduce the country’s reliance of copper imports and become more self-sufficient. It’s a long journey, and we are excited to have taken the first step!” he further added.

Gopalan Metals’ copper manufacturing facility will produce copper rods, copper flat, and copper wires of various types and sizes to cater to cable and transformer industries, automobile industries, electronics, solar energy and railways sectors, among others. By the end of 2024, the facility will start manufacturing domestic cables too.

The outlook for the copper market remains positive, despite geopolitical factors contributing to price volatility. As one of the oldest metals in common use, copper continues to be the most cost-effective electrical and heat conductor, not to mention the metal’s malleability and ductility, making it the preferred choice among wide-ranging businesses.