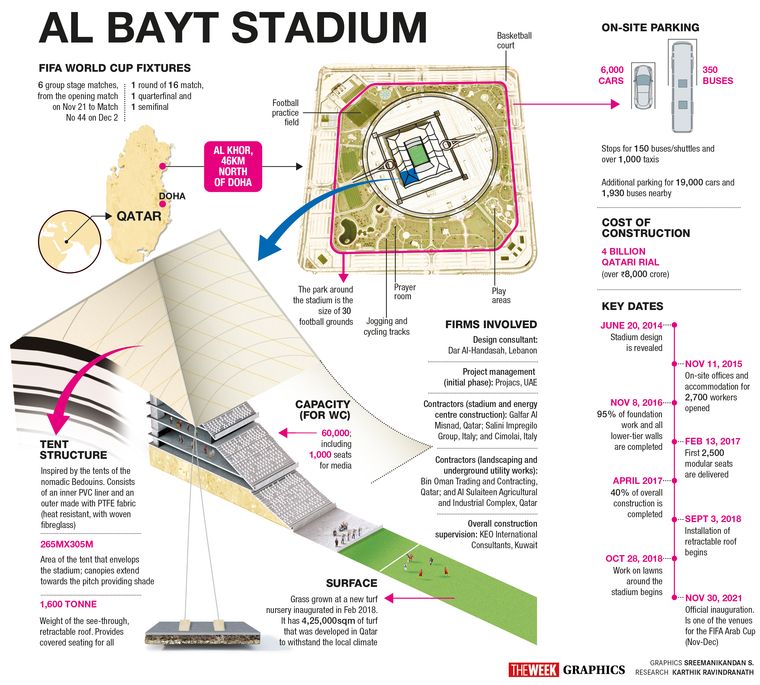

This distinctive and uniquely Qatari stadium is set to rival the best in the world, the FIFA website states emphatically about the Al Bayt Stadium.

The venue in Al Khor, 46km north of Doha, will host the opening match of the World Cup on November 21 and matches up to the semifinal stage. The most distinctive feature of the 60,000-capacity venue is the tent that envelops it. This was inspired by bayt al sha’ar—tents of the nomadic people (Bedouins) who have lived in the region for millennia. Traditionally, the tents have black stripes, like those on the arena’s exterior, and red and black patterns, which decorate the inside.

Qatari company Galfar Al Misnad was the lead contractor for the project. It was established in 1995 as a subsidiary of the Oman-based Galfar Engineering and Contracting, which was co-founded by P. Mohamed Ali.

Ali, who hails from Kerala’s Thrissur district, had started his professional career with the Border Roads Organisation, in Mizoram. He moved to the Middle East in 1970. Galfar Oman was established in 1972 and has grown into one of the largest construction companies in the Middle East, with a turnover of over $1billion.

In Qatar, the brand’s other landmark projects include the Katara Cultural Village and the Doha Metro Red Line North. Ali told THE WEEK that the Al Bayt Stadium was completed at a cost of 4 billion Qatari rial (over Rs8,000 crore). “It took around five years (including associated facilities),” he added. “At the peak, about 8,000 personnel were engaged; an average manpower of around 4,000 people were on site for almost two to three years.”

Sustainability and low energy usage was at the core of the design philosophy and this is reflected in the five-star certification that Al Bayt Stadium got from the Global Sustainability Assessment System. The light-coloured exterior reduces heat absorption and supports the new eco-friendly cooling technology used in World Cup stadiums (estimated to be 40 per cent more sustainable than existing methods). The tent’s canopies stretch towards the pitch from every side, providing shade, just like the tents shielded the nomads from the desert heat for centuries.

The size of the park area surrounding the stadium is equivalent to 30 football grounds, creating green lungs for Al Khor. The walkways to the stadium are lined with trees, and extensive taxi and bus facilities have been arranged to minimise the number of private vehicles on the roads. The roads were improved to ensure shorter travel times, which, in turn, would reduce the environmental impact of the event. A 1,600-tonne, see-through retractable roof lets in sunlight, which helps the turf grow and also helps to reduce energy consumption.

The tent covers an area of 265mx305m and consists of an inner PVC liner. The outside has been made with PTFE (poly-tetra-fluoro-ethylene) fabric—highly heat resistant fabric consisting of woven fibreglass. Most of the construction materials were made in Qatar, of which 20 per cent came from recycled sources. Key products like steel, wooden doors and precast concrete were “responsibly sourced”. LED lighting is used throughout the venue, as are water-efficient fittings.

Ali said that the environment provided by the countries in the Middle East for developmental activities was exemplary. “The best technology and the best innovations are always brought into and traded in the Middle East,” he said. “That means you get the latest of everything. Whatever is new is available. It has always been about an exchange of technology in the Middle East.”

After the World Cup, almost half the seats can be removed from the modular stadium and donated to other countries in need of sports infrastructure. The reduced capacity will be more in tune with the needs of the stadium going forward, and it will create space for facilities for the locals such as a shopping centre and multipurpose hall. There are also plans to convert the upper concourse of the stadium into a five-star hotel.